PE / PP Flange selection

Avoid leaks at flange connections & improve connection to metallic fittings.

Find out in this guide which PE / PP flange is the best choice for your application.

Pre-welded joints in PE and PP pressure pipes often cause problems. That is why Reinert-Ritz has developed various problem solutions with which flange connections can be reliably produced.

Find out how to select the flange in this help section:

- Why problems arise with PE 100 and PP welding neck seals

- in which order you arrive at the optimal decision

- how to use our selection tool to check whether the VP special flange is the best choice

- whether you rely on the welding neck or prefer to use our HP flange

Leakage and nominal diameter offset: the problems with standard plastic welding neck seals

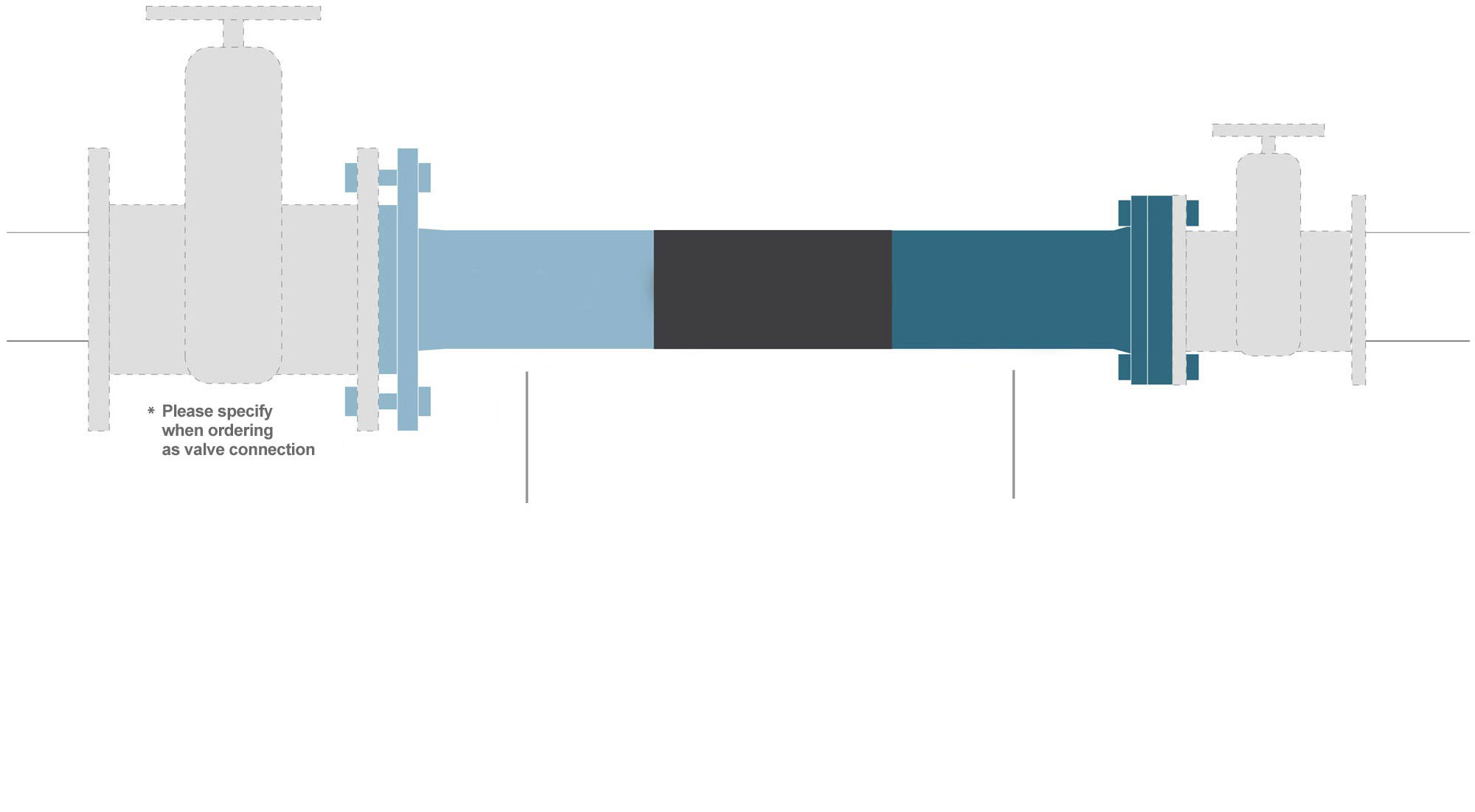

The first plastic pipelines, PE (HD-PE) and PP, appeared and the connection dimensions were adapted for pre-welded joints of metal pipelines. However, this caused two problems: the internal offset between the plastic and the steel/cast iron/GRP pipe and fittings in particular, and insufficient stability under many loads.

Reinert-Ritz has addressed these problems and today there are solutions to both problems: the special VP flange for the problem of internal misalignment and the HP flange for the problem of stability.

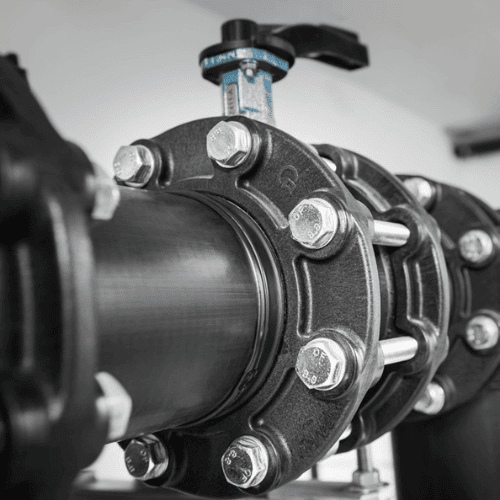

PE 100 and PP pressure pipes are used in many supply networks and industrial plants to transport liquids or gases. The pressure pipes are usually fitted with welding neck collars that are attached to metal flanges such as fittings. However, this design often has problems that can lead to leaks. The reason for the problems is that the internal diameters of many PE/PP pipe dimensions differ from the internal diameters of DN-oriented steel/cast iron or GRP pipes. As a simple solution, pre-welded collars are provided with a bevel on site. They are usually handled roughly with an angle grinder, which makes the collars unstable and can lead to leaks. To avoid these problems, it is important to select the right flanges at the planning stage.

The VP special flange is the solution for connecting PE 100 / PP pipes to fittings, steel, cast iron and GRP flanges.

The VP flange enables fittings to be integrated cost-effectively.

Installation is straightforward & the flanges are available in different sizes.

VP flanges are more stable than conventional flanges.

Minimal offset & improved flow properties as well as reduced deposits.

Flange selection with the virtual flange finder

You can use our flange finder to determine whether the VP special flange is the right choice for your application. Simply set the pipe diameter suitable for your application (e.g. DN/od 160) and read off to the left and right which DN/flange combination fits best:

PE 100 / PP welding neck collars: When is the standard welding neck collar the right flange choice for your pressure pipeline?

Designers and users of standard plastic welding neck seals know the problem. They are often difficult to seal during installation. In addition, leaks often occur at flange connections during the service life of the PE / PP pressure pipe. Some flange dimensions are easy to get tight, some require a lot of dexterity and others are highly critical. Pre-welded collars are not designed to be suitable for plastic, the plastic is overloaded and deforms over the course of its service life. The ambient conditions also influence the tightness of the connection — extreme cold or heat make installation even more difficult. The result: expensive maintenance and repair work as well as production downtime.

The typical problems with PE 100 and PP welding neck collars:

❗️ Standard plastic welding neck collars are often difficult to get tight

❗️ Leaks often occur at flange connections during the service life of the PE / PP pressure pipe

❗️ Welding neck collars are not designed to be suitable for plastic and the plastic is overloaded and deforms over the course of its service life

Flanges must be able to be mounted reliably even under difficult conditions. They therefore need sufficient reserves against overloading. Regardless of whether the overload is caused by pressure, environmental influences or assembly.

Pre-welding waistband checklist!

Many customers are unsure whether they can use PE 100 / PP bundles for their applications. There is often a mixture of positive and negative experiences with the use of welding neck bands. The decision also has an influence on the quality of the penstock.

We have created a checklist for our customers. You can use the checklist to assess how critical your application is. If in doubt, it is better to use the reliable HP flange.

Test our checklist now and decide whether pre-welding tapes are suitable for your application:

- Unerfahrene Monteure. Größer PN 10 ist in der Regel kritisch

- Kritische Anwendungen. Größer DN/od 500 (Flanschmaß DN 500) sind in der Montage herausfordernd

- Anwendungen mit zusätzlichen Belastungen. Freiverlegte Druckrohrleitungen, Biegebelastungen, Temperatureinflüsse sind kritische Anwendungen für den Standard-Vorschweißbund.

- Große Rohrdurchmesser. Kritische Anwendungen, bei denen Ausfälle zu höhen Schäden führen, sind dringend zu beachten.

- Abweichungen von den üblichen Druckstufen. Unerfahrene oder ungeschulte Monteure können ebenfalls ein Problem darstellen.

Are you unsure what the right flange connection is for you? Or would you like to do without a flange connection, but don’t have a solution?