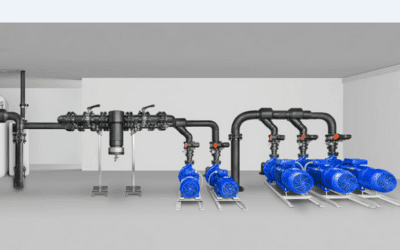

Construction work on our new building began in 2015. We had decided to plan a future-oriented pump room for our cooling water supply. However, we soon encountered problems for which we had to come up with new solutions. It was particularly challenging that parts of the pipeline were laid under the foundations and therefore months before the pump room was removed. To cope with the limited space, we had to come up with a flexible solution. Thanks to the clever planning and hard work of our team, the pump room could be realized as planned. The result is impressive: The pump room is functional, easy to maintain and also future-proof thanks to the PE 100. Our customers also benefit from the newly found solutions to problems. Find out which solutions we have used:

Corrosion-free and reliable PE 100 flange connections in the pump chamber

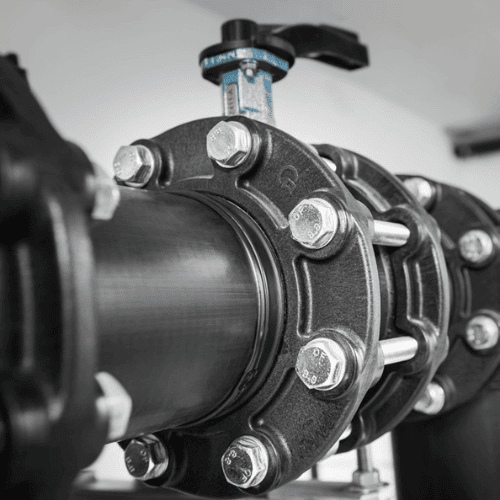

Flange connections are one of our core competencies. We have developed flanges that are highly reliable and solve many problems in PE 100 pipeline construction.

In our pump room, we have installed our flanges in metal replacement quality for the first time. 100% plastic and maximum reliability. Your advantage: No corrosion and less weight.

Our HP ME flange is the reliable loose flange connection with many advantages:

Our special flange VP was specially developed for connecting PE pipelines to pumps, fittings, butterfly valves and steel or GRP pipelines.

Configurable PE 100 filters for the pump room

Our PE 100 filter is the best choice for you if you need a flexible filter. Thanks to the flexibility of our molded part production, we can configure the filter entirely according to your wishes. This means that the forward and return flow can be flexibly positioned in the configuration.

It is also easy to use, as the filter can be backwashed and opened using a practical quick-release fastener.

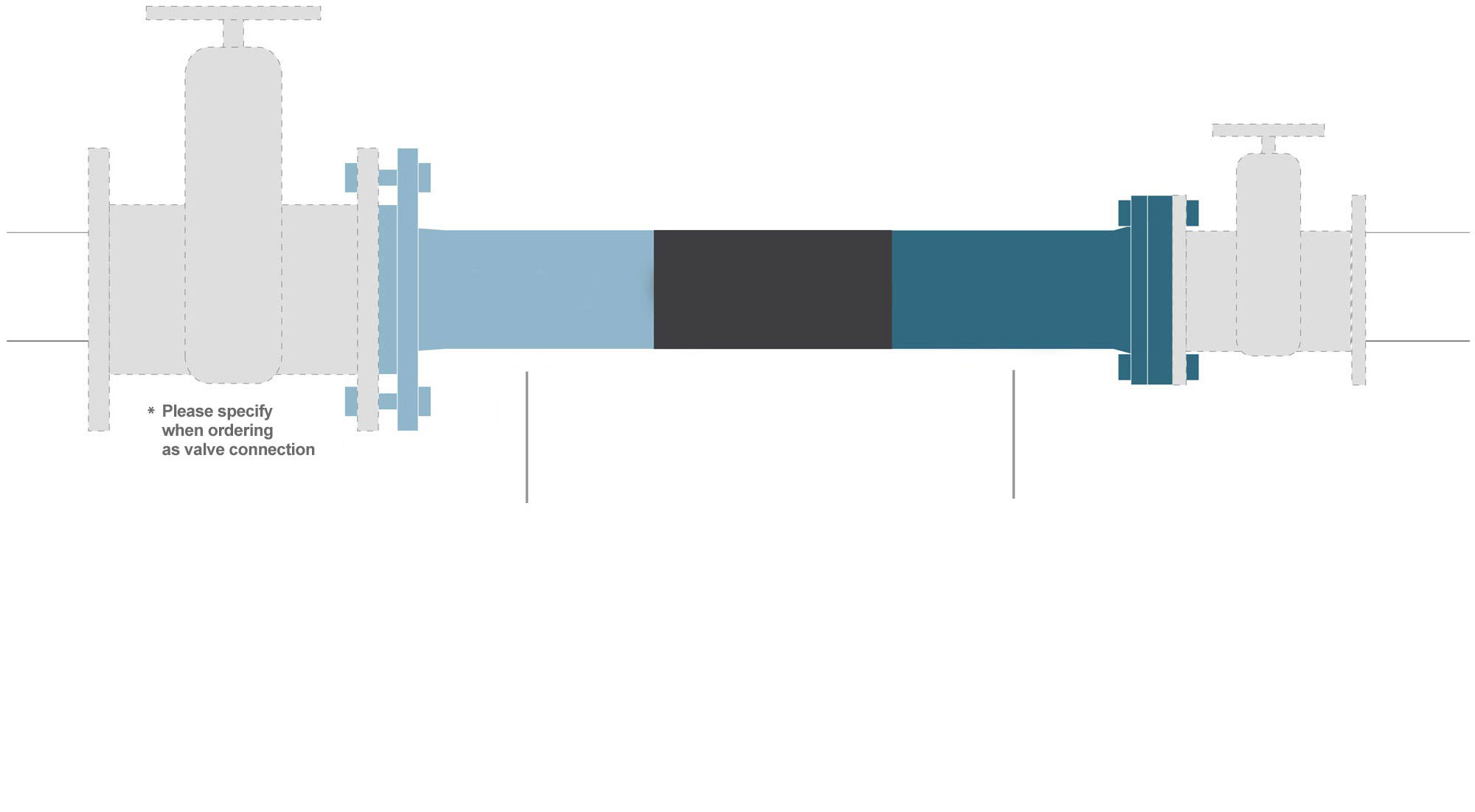

PE 100 pump transitions — flow-optimized, flexible or adjustable

The ideal pump transition is not only flow-optimized, but also offers flexible options for connecting measurement and control technology. This allows you to operate your pumps more effectively and save costs at the same time.

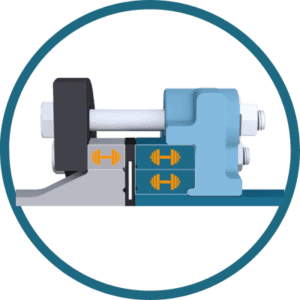

The Quick-Twist fitting and extension piece is a real breakthrough in pipeline construction. Thanks to the simple twist lock, it can be adjusted in an instant — without any threaded rods or fiddling around. The best thing about it: Quick-Twist is completely corrosion-free. So you can be sure that your pumps and valves will be perfectly maintained in the future.

Quick-Twist is ideally suited for connection to valves (gate valves, butterfly valves, MID, …) and pumps on both the suction and discharge side.

PE 100 floor bushing with power transmission and sealing — a clever solution for the pump room

Planning a PE 100 pipeline in the Riem Arcaden in Munich was a challenge. One question was how PE 100 pipelines can be routed vertically through floors and at the same time reliably transfer the forces into the structure. Together with the responsible planners, a PE 100 fixed point collar was developed especially for connection to buildings. The collar is designed to reliably transfer the forces between the PE 100 pipe and the wall or floor. In addition, a large-volume seal seals the core drill hole so that no water or dirt can penetrate. You can rely on our many years of experience and our service.

We like the solution so much that we also use it in our pump room. The water reservoir is located under the pump and the risers on the suction side are fixed to the floor with our PE 100 fixed point collar.

Incredible flexibility that provides planning security — PE 100 push-fit socket for a very special application

The planning of our pump room presented some challenges! One particular challenge was the connection of a pipeline line, which was laid under the foundation at a very early stage of construction. The space available did not allow the pumps, tanks and heat exchangers to be moved. So we had to find a way to compensate for the inaccuracies in the shell.

Our idea: a socket that can be connected to the reinforcing steel. This allowed the position of the pipeline to be fixed well. The highlight of the push-in socket is that it is flexible in terms of insertion depth and insertion angle. Thanks to this innovation, we were able to equip the pump room as planned!

PE 100 intermediate flange distributor — compact and flexible

The intermediate flange T‑piece is a flexible and popular solution, especially where space is limited. The T‑pieces are connected via flanges and can be configured with different outlets. You can also decide whether the intermediate flange T‑piece is configured with a weld end or threaded connection.

Even more flexibility: the intermediate flange distributor offers you the opportunity to bring even more flexibility to your installation. You can set outlets during installation or at a later date. The outlet positions are sealed with dummy plugs, which can be replaced by weld-on sockets. This allows you to set up to four outlets flexibly.