PE branch

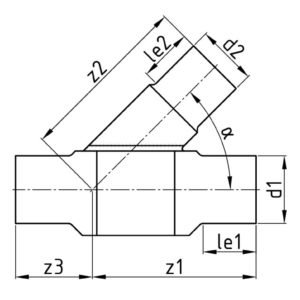

Pressure-resistant branches with equal and reduced outlets

Branches made of PE (polyethylene) are an efficient and cost-effective way of extending or adapting piping systems.

Using a PE branch in piping systems is an efficient and cost-effective way of extending or adapting pipelines.

It is particularly suitable for use in water supply, waste water disposal and gas supply.

PE branches are characterized by their high flexibility, resistance and durability and are therefore a popular choice for the installation of piping systems.

The advantages of PE branches: they are corrosion-resistant, chemical-resistant and resistant to temperature fluctuations.

This makes them particularly low-maintenance and gives them a long service life.

The Reinert-Ritz branch for welding is characterized by its full pressure resistance.

It is easy to transport and install.

The PE branch is also optionally available in angles between 45° and 90° and allows a high degree of flexibility when integrating it into a piping system.

The branch has long welding ends and is therefore well suited for E‑socket welding.

This is further enhanced by directly available reducers at the outlet, which also makes the fitting compact and lightweight.

Branches with other angles are available on request.

Send us an inquiry directly here A PE branch is the ideal solution for extending or adapting piping systems.

It not only offers a high level of functionality, but also a sustainable and cost-efficient solution.

With a PE branch from Reinert-Ritz, you can count on quality and reliability for your piping systems.

Tender text

PE100 branch The fittings to be offered must be made of material in accordance with the PE100+ Association and comply with DIN EN 12201 in terms of dimensions, tolerances and quality requirements. Proof of production on the basis of a quality assurance system in accordance with DIN EN ISO 9001 must be provided. A certificate in accordance with DIN EN 10204 must be provided by the manufacturer for all molded parts. Depending on the dimensions, the molded part must either be injection molded or manufactured from several components of homogeneously extruded semi-finished product using a turning or milling process and the wall thicknesses in the area of the welds of the components of the base body must be reinforced accordingly in order to ensure the required reinforcement and thus high stability of the molded part. Semi-finished products made from winding rod or other subsequently applied reinforcements are not permitted. The branch must be made of PE100. The pipe connections must be designed as spigot ends in a sufficiently long form for HE butt welding or HW welding corresponding to the nominal width of the pipe. The inner beads of the HE butt weld joint must be removed. The outlet can be reduced and optionally designed to be flush with the floor

Weiterlesen

Normen/Richtlinien

DIN EN 12201, DVS 2207, DVS 2210, DIN EN 10204, DIN EN ISO 9001, DIN EN ISO 50001Zulassungen/Zertifikate

Abnahmeprüfzeugnis 3.1 nach DIN EN ISO 10204 am Halbzeug vom verarbeiteten Rohstoff mit Angabe von MFR und OIT; nur PE100 Material gem. PE100+ Association

Hersteller zertifiziert nach ISO 9001:2015 und ISO 50001:2011

Hersteller:

Reinert-Ritz GmbH oder gleichwertigLeistungsbeschreibung:

PE100 Abzweig …°, für … [Medium]-Leitung, druckklassengerecht, mit langen Schweißenden für Einbau in eine Leitung der Dimension DN/OD … SDR … Nenndruckstufe PN …Liefernachweis:

Reinert-Ritz GmbH

Ernst-Heinkel-Straße 2

48531 Nordhorn

Tel.: +49 5921 8347–0

Fax: +49 5921 8347–25

www.reinert-ritz.de

Email: contact@reinert-ritz.com