Inspection hatches

Openings in the piping system for installation via manholes

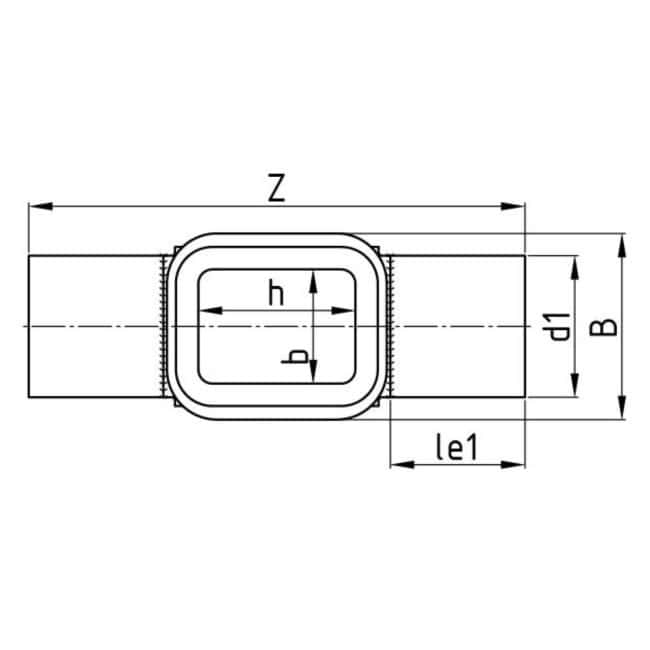

The main bodies of the inspection openings are made from homogeneously extruded hollow bar. Different versions according to the pressure requirements in the piping system are available. The inspection openings can be implemented in rectangular shapes. The cover plates of the inspection openings have a pig-friendly shape on the inside so that floating of the pig during cleaning is avoided, and the pigging process can be performed without interruption, which saves time and costs.

Specifications

Tender text

PE100 inspection hatch

General preliminary remark

The fittings to be offered must be manufactured from material in compliance with the PE100+ Association and according to DIN EN 12201 with respect to dimensions, tolerances and quality requirements.

Proof must be provided that they were manufactured on the basis of a quality assurance system in accordance with DIN EN ISO 9001.

For all fittings a certificate in accordance with DIN EN 10204 must be submitted by the manufacturer.

The body of the fitting must be manufactured from a piece of homogeneous semi-finished material so as to ensure the required reinforcement and therefore high stability of the fitting.

Semi-finished materials manufactured from wound rods or the subsequent application of other forms of reinforcing are not permitted.

The inspection hatch must be manufactured from PE100.

It must be pressure class-compatible as required and consist of a housing with a rectangular cover for pig running as well as external reinforcement.

All bolts as well as flange components and, if necessary, cover reinforcement ribs must be delivered hot-tip galvanised.

The seal must be manufactured from media-resistant material.

The pipe connections must be designed as a spigot in a shape sufficiently long for HE butt welding or HW welding and must have the same nominal diameter as the pipeline.

The inner beads of the HE butt welding joint must be removed.

Optionally a flushing connection can be provided on the body or in the cover.

In addition, the inspection hatch can be fitted with a support structure according to specifications.

Alternatively the cover can be delivered in a round version.

The pipe connections can be optionally fitted with flange connections appropriate to the isolation valve to be used.

The flanges used must be in conformity with the selected pressure class and be manufactured either from steel with appropriate protection against corrosion or from corrosion-free, fibre-reinforced plastic

Standards/guidelines

DIN EN 12201, DIN EN 1092-1, DIN 4124, DIN EN 1671, DWA-A 116-2, DVS 2207, DVS 2210, DIN EN 10204, DIN EN ISO 9001, DIN EN ISO 50001

Permits/certificates

Acceptance test certificate 3.1 according to DIN EN ISO 10204 for the semi-finished material from the processed raw material with indication of MFR and OIT; only PE100 material in compliance with PE100+ Association

Manufacturer certified according to ISO 9001:2015 and ISO 50001:2011

Manufacturer:

Reinert-Ritz GmbH or equivalent

Performance specification:

PE100 inspection hatch with rectangular (or round) cover for … [

medium

] pipeline, pressure class-compatible up to … [4 bar or 16 bar], for installation in a pipeline made of ...

[

PE/PVC/…

] of the size DN/OD ... x ... mm SDR ...

Proof of delivery:

Reinert-Ritz GmbH

Ernst-Heinkel-Straße 2

48531 Nordhorn

Tel.:

+49 5921 8347-0

Fax:

+49 5921 8347-25

Email: contact@reinert-ritz.com